- design target:

quad-rotor aircraft with all four rotor tilt, which consists of Arduino family products only.

+aerodynamic practicality and complete dynamic control during all phase of flight(VTOL mode, plane mode, and in between them).

(thumbnail)

- overall scheme

(not the actual wiring, only for intuitive understanding)red lines for 11.1V(also 11.1V PWM) wiring, orange lines for 5V high amp wiring, black line for low amp wiring.

selection of Arduino Mega: lots of pins(including PWM)

mpu6050 for attitude sensing, nRF24L01 for radio communication

- rotor arrangement and design direction

Several concepts were proposed and simulated by Simscale.

V1: first baseline model for this project. Aluminum plate reinforcement on the side of the main form board structure is used to strengthen the board and the connection between the board and the motor-mounting arm. CoM is designed to be located at the middle of the front and rear motor-mounting arm. The overall arrangement avoids prop wash blockage by the main wing or the stabilator in VTOL mode. Prop wash-wing interaction is considered to reduce the bending moment of the wing and more desirable pressure distribution(less pressure difference towards the tip).

V2 & V4: Both uses canard at front, but especially V4(lower picture) is aimed to control the stall characteristic of the main wing. However, both failed to give enough longitudinal stability since the canard in front of CoM tends to overcome the rate of pitching moment increasing from the main wing as AoA increases. By simple calculation, we could have very small area for canard to sufficiently reduce the adverse effect in longitudinal stability, if we were keen to use this main wing. Delta wing may give enough slope for pitching moment increasing, but it will be hard to avoid rear prop wash in VTOL mode and it is tricky to shape with hot wire foam board cutter.

V5: This configuration was aimed to reduce the p-factor induced by the downwash of the main wing. The stabilator-vane indeed provided an airflow almost normal to the rear prop, which should have reduced the p-factor. However, it failed to give enough longitudinal stability and the p-factor effect in this scale was too small, thereby it was deemed impractical.

V6: Back to V1, but this is more refined version. Main central plate structure consists of a form board and Fomex sandwiching it from both sides. Fomex is good at resisting tension and therefore it is expected to be enough reinforcement, but also much more light weight than the previous aluminium plate reinforcement structure. The stabilator location was refined, so that it can avoid any turbulent air generated by the rear motor mounting arm, which might decrease the control effectiveness or even cause stabilator stall.

- CFD result of the final design

propwash & main wing downwash induced stabilator stall: It needs to be fixed by adjusting AoA of the stabilator root section or using some additional devices(eg. slots or guide vanes) to make it attached.

wingtip vortices: Maybe refined later, especially the one comes from the second and third elements, which seems quite strong.

pressure distribution: the effect of the -x rotation of the front prop and +x rotation of the rear prop is pronounced.

propwash visualization using Y-plane(top), particle trace(middle), and vorticity(bottom). The front prop tip vortices barely brushes tip of the rear prop. One of the main considerations in mounting those props were reducing blade-vortex interaction which effects the propeller efficiency and noise.

- chassis construction

made of: lots of form boards, Fomex, wooden sticks, and 3D printed parts(PLA)

[software]

- flight configuration variables

- main loop

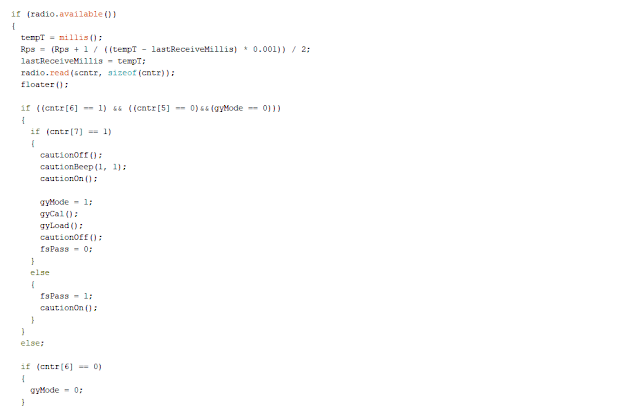

you can observe following features in the main loop:

- fail safe

- gyro attitude correction or acro mode selection

- motor arming

- flight control value calculation and output to the ESCs and servos.

- radio & mpu6050 update rate calculation

- arduino timer overflow prevention

- main control function(calWrite) & auxilary functions

auxilary functions:

- antiWU: anti wind-up of the I gain

- DPGrefFunc: PID gain refinement corresponding to the rotor tilt(Drone mode to Plane mode)

- POSrefFunc: attitude offset for gyro corresponding to the rotor tilt (it needs to hover with 10 deg pitch up due to the ground effect difference of the front and rear prop, but not in plane mode. I am using the terms "drone mode" and "plane mode", but there is no kind of discontinuity in flight mode. It is just for explanation.)

- DPdtrefFunc: refinement for mapping PIDgains to actual moment. DPdtrefFunc is about overall geometry effect in flight mode transition, where DPGrefFunc is more about PID tuning. They are kind of redundant, but allows more convenience in tuning.

- trimAdder: PID gain offset

- PIDgExm, echgExm, thtLvExm: They simply check if the values are in the proper range.

- tht_wExm, sbt_wExm: They check the angular velocity of the rotor & stabilator tilt.

- thrMod, thtMod, sbtMod: throttle, rotor & stabilator tilt modeling. They maps the calculated value to actual PWM value. They may also be used to compensate any geometrical effect(e.g. linkages)

Refer the picture below for understanding deltX, deltY, thrLv, etc.

Note that "kg_sbt" controling stabilator gain with arctan function(less movement in drone mode).

- structure of tht_wExm(similar goes for sbt_wExm)

- throttle modeling

since the physical map of the PWM input and actual thrust is not linear, throttle modeling is required.

thr_w(0 ~ 1000) to PWM value(1000 ~ 2000) mapping

- remote controller

made of: lots of form boards and potentiometers. The two arduino joysticks below are not for flight control(they have too much play).

- flight demonstration

- introspection

- 60 loops(attitude calculation and refinement) per second was acheived but it was not enough. Due to this, overall PID gains must be decreased, which hampered control effectiveness.

- the aircraft was very sensitive to wind compared to conventional multicopters. Surely this is due to the large plate-style structures and wings. Combined with less control effectiveness, this made this aircraft almost unflyable in wind.

- Rear prop-stabilator interaction resulted in sudden change of pitching moment while transition. Fine tuning of DPGref or DPdtref might solve this issue but it is too time consuming. Again, with low control effectiveness, this made transition and plane mode not feasible.

- As discussed in [CFD result of the final design], there are some parts need to be refined.

.jpg)

Comments

Post a Comment